There are several factors that influence pressure range selection. The following excerpt from ASME B40.100 explains along what portion of the scale the gauge should typically operate.

ASME B40.100-2005

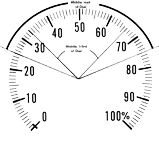

4.3.1 Operating Pressure. The pressure gauge selected should have a full-scale pressure such that the operating pressure occurs in the middle half (25% to 75%) of the scale. The full-scale pressure of the gauge selected should be approximately two times the intended operating pressure.

4.3.1 Operating Pressure. The pressure gauge selected should have a full-scale pressure such that the operating pressure occurs in the middle half (25% to 75%) of the scale. The full-scale pressure of the gauge selected should be approximately two times the intended operating pressure.

Should it be necessary for the operating pressure to exceed 75% of full scale, contact the supplier for recommendations.

This does not apply to test, retarded, or suppressed scale gauges.

Bourdon tube pressure gauges are designed and built to operate primarily in the middle third of the scale range so that when the gauge is mounted in a vertical and upright position, the pointer will be as close as possible to the 12 o’clock position when reading pressure at normal operating conditions.

Although the gauge will operate full scale, there are other considerations to take into account. If the gauge is primarily operating at the bottom of the scale (near zero), the accuracy or readability would be improved by using a more appropriately applied lower range pressure gauge. (SEE ASME B40.1-2005) If, on the other hand, the gauge is operating at the top of the scale (near the maximum pressure range of the gauge), the life span of the gauge may be decreased, particularly if the gauge encounters high cycling, temperature extremes and/or excessive vibration.

- A bourdon tube is a curved and hardened or formed piece of metal designed to move a certain amount based on the amount of force applied, then, return to its original shape when at rest, just like a spring. As with any spring, the bourdon tube will fail after extended use. This failure could be as simple as a loss of accuracy, failure to return to zero, or a release of the pressurized medium into the case of the gauge or atmosphere. Note: Extended use could be time in service, number of pressure cycles and extent of the pressure cycle. The larger the number of applied pressure cycles and the greater the extent of the pressure cycle, the earlier the failure will occur.

- Bourdon tubes are by design highly stressed, especially in ranges over 1000 psi. Continuous operation at full scale will result in early fatigue failure and subsequent rupture.

- Continuous, rapid pointer motion will result in excessive wear of the internal mechanism and cause gross errors in accuracy, the pressure indicated and, also, possible early fatigue failure of the bourdon tube. If the pointer motion is due to pressure pulsations, a suitable dampener should be used between the pressure source and the gauge.

To choose the best range for your application, the follow factors must be considered:

- The normal operating pressure or average system pressure.

- System pressure limits (bot maximum and minimum).

- Primary concern between readability, accuracy and/or durability.

See ASME B40.1 for additional details.